Building Codes and Appliance Standards

Potential emissions reductions from building codes and appliance standards.

Residential and commercial buildings represent roughly 20% of delivered energy use and more than 50% of electricity use worldwide. Buildings in cities are particularly heavy energy users and the continuing urbanization trend could nearly double urban populations to 6.3 billion people by 2050, increasing demand for lighting, air conditioning, and consumer devices – meaning energy use in buildings will become more intense every year.

Well-designed building codes and appliance standards are two of the most effective policies to ensure new and renovated buildings are as efficient as possible and decouple demand for energy from demand for building services. Used in combination, these policies can achieve at least 5% of the emissions reductions needed to achieve the two-degree Celsius target.

Building codes, or regulations that impose requirements on building design and construction, typically set minimum energy technology requirements or efficiency performance criteria that new or modified buildings must meet. When effectively written and enforced, building codes are a crucial way to save energy, reduce emissions, and save money

Appliance standards set minimum energy performance requirements for new appliances, similar to energy efficiency building codes, and typically specify the maximum amount of energy an appliance of a given capacity and type may use in order to perform a specific service. When properly implemented, standards drive down emissions year after year while achieving net savings for society.

Building codes and appliance standards are a key policy for reducing emissions from the building sector, which is particularly important in rapidly urbanizing countries, and they are effective at overcoming various market barriers common in the building sector that limit the effectiveness of economic incentive policies.

Policy Description and Goal

Building Codes

Building codes are regulations that impose requirements on the design and construction of buildings. Codes can serve a variety of social purposes, such as protecting the health and safety of occupants and reducing impacts on nearby public spaces. However, when the goal is to limit energy use and emissions, building codes typically set minimum technology requirements or performance criteria that new or modified buildings must meet. For example, building codes may specify how effectively windows or walls must insulate the interior from exterior temperatures or set a required efficiency level for central heating or air conditioning systems.

In contrast, whole building energy performance standards specify a maximum energy use for the entire building rather than for individual components of that building. These standards may be used for code compliance, in voluntary certification programs, to determine eligibility for tax incentives, and for other purposes.

Appliance Standards

Similar to energy efficiency building codes, appliance standards set minimum energy performance requirements for new appliances. Appliance standards typically specify the maximum amount of energy that an appliance of a given capacity and type may use in order to perform a particular service. An appliance standard might mandate that every specific model comply with the standard, or it might allow manufacturers to meet the standard via a sales-weighted average of the appliances of a given type that they sell.

An important distinction between building codes and appliance standards relates to monitoring and enforcement. Most buildings are one-of-a-kind or, at most, are built in small numbers and are site-specific. Buildings “are the largest handmade objects in the economy.” Accordingly, inspections and energy audits of every individual building may be necessary to determine whether those buildings comply with a performance standard.

In contrast, large numbers of identical appliances are produced in factories, and their energy efficiency can be tested “upstream” on just a few units provided by a manufacturer or importer during a verification process. Once in wide distribution, appliance standards also require ongoing enforcement to ensure manufacturers aren’t cheating standards.

For example, check testing, where for-sale products are periodically randomly checked and tested, and import controls can help uncover cheating by manufacturers. However, appliance standards are more suited to initial verification than building codes, so they are often easier for lower- income regions to implement. In both instances follow-up enforcement is important.

When to Apply This Policy

A key element of both building codes and appliance standards is their ability to mandate performance improvements that are economically beneficial to consumers yet for a number of reasons fail to be adopted in the market. Because of the characteristics of the building sector, market failures of various sorts occur almost everywhere, so building codes have very broad applicability.

One common example is a misalignment of incentives between those who pay for energy and those who pay for buildings and appliances. Many households and most businesses do not own the buildings they occupy; rather, they are tenants. Property owners lack an economic incentive to improve the energy efficiency of the building because the tenants are generally responsible for paying the utility bills. (Information barriers and other issues pertaining to human psychology make it difficult to price energy efficiency upgrades into the rent charged to tenants.) Meanwhile, tenants may be prohibited from making major changes to the building.

Even if allowed, tenants may balk at putting money into buildings that they do not own, particularly if they believe they might move before the capital cost is recouped via energy savings. Building codes and appliance standards set a minimum level of performance that building owners are expected to provide, thereby ensuring that the energy savings (which are larger than the capital cost) are realized.

Examples of other market failures that are partially mitigated by building codes and appliance standards include consumers’ short or inconsistent discount rates, insensitivity to rebate or subsidy policies, imperfect information, and high transaction costs. Amory Lovins provides a more detailed discussion of various engineering and institutional reasons for inefficient building design and construction.

Efficiency improvements do not necessarily increase the cost of equipment relative to less efficient models, because the policy can spur companies to engage in research and development (R&D) that lowers the cost of efficiency improvements over time. (Thus, the fact that a more efficient appliance may be more expensive than a less efficient appliance today is not a good guide to whether a performance standard would result in increased appliance costs in future years.) For example, refrigerator efficiency in the U.S. has improved since 1972, while actual consumer prices have declined and refrigerated volume has increased. These efficiency improvements were driven in part by a series of standards, beginning in 1978.

U.S. refrigerators prices have fallen while becoming more efficient and larger. Source: Appliance Standards Awareness Project.

Building codes and appliance standards can and should be designed to improve over time, thereby providing a clear signal to manufacturers that R&D investments in efficiency will pay off. When the standard comes into effect, a company that invested in R&D can produce better or cheaper appliances and building components than are available from competitors. This allows the manufacturers to gain market share. If all manufacturers engage in R&D, this drives down prices across the board and benefits consumers.

In contrast, policies that provide a rebate for the most efficient products on the market tend to encourage individuals and businesses to purchase these products, but they often do not encourage manufacturers to engage in R&D and improve their products’ performance over time (because the rebate qualification thresholds typically are based on the range of products already available in the market). Product labels, on the other hand, have been shown to motivate manufacturers to engage in R&D and meet increasing efficiency requirements.

Another advantage of building codes and appliance standards is their low cost to implement. A rebate or subsidy for efficient products may cost government a great deal of money because it must pay some fraction of every rebate-qualifying product that is sold. A tax on inefficient products or especially a tax on fuel may cost building owners or occupants a significant amount of money. A standard does not require large payments between government and energy users throughout society.

The only government costs relate to the initial establishment of standards (e.g., technical analysis of products, meeting with industry) and the monitoring and enforcement of the standards. These costs may be lower for appliances, where the standard can be enforced upstream, at a limited number of points of manufacture or importation. Building component standards are harder to enforce because they may involve inspections of individual buildings, but nonetheless, they are cheaper than many alternative policy options.

Additionally, the cost of codes and standards can be scaled by varying the extent and type of analysis and stakeholder engagement. Greater resources will yield more rigorous standards, but even without this level of rigor, standards can be effective.

Another benefit of standards for appliances and some types of building components is the ability to cause efficiency improvements in areas beyond the control of the policymaker. For example, if a large region such as California implements stringent efficiency standards for televisions, manufacturers that want to sell televisions in California must produce standard-compliant models that will appeal to consumers. They may be obligated to conduct R&D in order to maintain their ability to sell attractively priced and functional televisions in California in the future. They also must retool their assembly lines to produce these improved televisions. Having already made these R&D and manufacturing investments, the appliance manufacturer may determine that it is more cost-effective simply to sell the standard-compliant televisions throughout the U.S. rather than maintain production of less efficient televisions that can be sold only in some states. The larger the number of regions that enact standards, the more likely manufacturers are to choose to comply with those standards universally rather than only in the jurisdictions where the standards are in force.

Detailed Design Recommendations

Create Long-Term Certainty to Provide Businesses With a Fair Planning Horizon

It may take years for manufacturers of building systems and appliances to make the necessary R&D investments and changes in their manufacturing lines that reduce energy consumption without adding greatly to the building’s cost and without compromising other performance characteristics.

If standards are set just a few years at a time, businesses may be unsure whether standards will continue to become more stringent in future years. This means they will not know whether modest investment in near-term improvements is sufficient or whether a larger investment in a new technology or major design change might be worthwhile.

Because the process of selecting a building site, acquiring building permits, obtaining financing, and constructing a building can stretch for many years, it is particularly important for architects, engineers, and financiers to know building code requirements over a sufficiently long time horizon.

Standards can help companies that manufacture appliances and building systems justify investments in R&D and energy efficiency to their shareholders, who otherwise might be skeptical of the value of these expenditures. Companies that make a serious commitment to R&D may even see this as their competitive advantage.

Build in Continuous Improvement

Building codes and appliance standards are valuable because they increase efficiency of the building stock and eliminate the worst-performing buildings and products over time. If the standards are allowed to stagnate, they are not serving their primary purpose. For example, the U.S. Government Accountability Office estimates that failure to update appliance standards in the U.S. in the 1990s and early 2000s will cost consumers at least $28 billion through 2030. Forgone energy savings imply further damages, such as greater emissions of pollutants that cause premature deaths and drive climate change.

Focus Standards on Outcomes, Not Technologies

Standards should set energy performance targets rather than specifying particular technologies to be used. This allows architects and engineers the maximum flexibility in designing buildings and products that achieve their financial, aesthetic, and functional goals while achieving the requisite energy performance.

Buildings are diverse and can have features that are site-specific and are particular to the building’s intended purpose, making prescription of specific technologies unwise. The same air handling, heating, or envelope components that work well in an office building may be ill suited for a residential building or a warehouse.

For example, to reduce lighting energy consumption, extensive use of skylights, windows, other openings, or reflective surfaces (collectively called daylighting techniques) may be suitable for a building on a site with sufficient sunshine and intended to be used primarily in the daytime, but these techniques may not achieve the desired energy savings in a building on a different site or intended to be used at night.

Prevent Gaming via Simplicity and Avoiding Loopholes

Standards should be written with simplicity and clarity to prevent manufacturers and building designers from gaming the standards. Standards should be written in consultation with a diversity of experts and stakeholders and carefully checked by government scientists and other experts for possible loopholes.

In general, specifying overall energy performance targets with as little variance as possible, given building characteristics, will tend to minimize loopholes, although the resulting standard may be more difficult for some building types to comply with than others.

Additional Design Considerations

If building and appliance performance standards are designed according to the principles just described, there are only a few remaining points to consider.

Require Thorough Monitoring and Enforcement

To be effective, building codes and appliance standards must be subject to rigorous testing and enforcement. Local governments must have adequate funding to properly review building plans and to hire, train, and dispatch building inspectors. Building inspectors should be assigned randomly to each building or development, to avoid corruption, and for big projects, inspections should be alternated between two or more inspectors. Similarly, appliances must be subject to random, standardized testing to ensure they perform in accordance with an appliance standard.

Where enforcement is weak, manufacturers and building owners will often fail to meet the standards. For example, in China, where enforcement staff and funding are inadequate, third-party testing has demonstrated that many appliances fail to meet national standards, even though manufacturers self-report their appliances as up to code. Similarly, China worked to develop an improved building inspection system in the late 2000s.

Before this system, just 21% of medium and large construction projects in urban areas complied with building codes. The improved inspection system greatly increased compliance rates of these types of projects. However, there are almost no inspections of rural developments, nor of small developments in urban areas, so compliance rates among these building types are unknown (and probably low).

To avoid cheating by manufacturers or importers of appliances, the government should use a randomized process to purchase appliances to be tested for energy efficiency rather than allowing the manufacturer or importer to submit a unit for testing. The government should conduct spot tests, to complement manufacturers’ certifying that their own products comply with standards. In regions with strong economic and legal infrastructure, these tests can be occasional, happening only every few years. But in regions with weaker infrastructure, government should test more frequently.

Ensure Sufficient Knowledge of Green Building Design and Construction

Buildings are almost always designed and built by hand, not mass produced in factories. The ability of a building to meet energy efficiency standards depends in part on the ability of that building’s designer to anticipate and correctly design energy-saving features and for the construction companies and contractors erecting the building to use best practices.

Small matters such as proper air sealing of ducts can make a substantial difference in final energy use. Construction firms must be attentive to energy-efficient construction and must build structures of high quality. Therefore, they must have the necessary knowledge and capabilities.

Government can help by providing or funding education and training programs for the building industry and leading by example through performance- based building procurement, in which procurement contracts for new buildings specify minimum energy performance criteria.

Government can also ensure that energy use is monitored, and buildings that fail to meet the energy efficiency standard should be penalized and the defects immediately corrected at the owner’s expense. This gives the building owner an incentive to ensure the building achieves promised energy savings. The building owner can then select the firms with the best reputations for energy-efficient building practices and include energy performance requirements in construction contracts.

Couple Codes and Standards With Strong Complementary Programs

Building codes and appliance standards rely on stock turnover to achieve energy savings. Appliances often take more than 10 years to reach the end of their lifetimes, and some building components, particularly parts of the building envelope, can last 50 years or more.

Therefore, it may be many years before the full benefit of building codes and appliance standards is realized. To help mitigate this problem, building codes and appliance standards should be coupled with strong retrofitting programs (also known as retro-commissioning), including subsidies or other incentives, to help accelerate stock turnover.

Applying strong building codes in places that are rapidly urbanizing, such as India, China, and Nigeria, can affect buildings when they are first built rather than waiting for building turnover, but rapidly developing and urbanizing areas are also some of the places with the greatest enforcement challenges, so codes may be a higher-risk, higher-reward policy option in these places.

Building codes and appliance standards generally affect only the bottom of the market, removing the worst-performing products each year. They do not provide incentives for people to purchase the top-performing products instead of products that are minimally compliant with the codes. This drawback can be remedied by pairing codes with other policies that promote uptake of the top-performing products, such as clear labels that show energy savings, subsidies or rebates for the most efficient products, and carbon pricing that raises the costs of owning inefficient products.

Case Studies

California’s Energy Code

Title 24 of California’s Energy Code was established in 1978 to provide a single coordinated, comprehensive building energy standard that governs the design and construction of all California buildings, associated facilities, and equipment. In particular, Part 6 of the California Energy Code contains requirements for building energy use and energy efficiency. The standards require a minimum energy efficiency level and provide buildings with two options for meeting the standard by using either performance-based or prescriptive methods.

The code also offers voluntary “Reach Standards” for buildings that strive to achieve additional energy savings. The California Energy Commission (CEC) has approved a handful of energy analysis computer programs, including both public and private domain software, to test for building compliance. A building permit is required to construct or substantially alter a structure. To receive a permit, builders must submit project plans to city officials and be in compliance with Title 24 and other regulations. The CEC has a “Building Permit Violation Referral form” that anyone can use to report unpermitted construction activity.

Title 24 requirements are updated by the CEC on a 3-year cycle. Six California utilities operate a Codes and Standards Enhancement Initiative, which supports the standard revision process through public meetings and research to help identify areas that show promise for energy savings potential. For the upcoming Title 24 revision, the Codes and Standards Enhancement Initiative provides guidance on improvements in lighting, HVAC, indoor air quality, building envelope, water heating, and demand response. Members of the public may also propose measures for consideration. This update process helps ensure that Title 24 requirements do not become stagnant and that tighter standards remain achievable in commercial practice.

Title 24 has saved more than $74 billion in electricity bills and helped keep California’s per capita electricity usage stable over the last four decades, even though state gross domestic product (after adjustment for inflation) more than tripled during this period. The CEC has found that since 1978, the standards have avoided “more than 250 million metric tons of greenhouse gas emissions (the equivalent of removing 37 million cars off California roads).” It estimates that the newest, 2016 revision of the Title 24 standards will save a typical residence $7,400 over the course of a 30-year mortgage while increasing the initial price of the residence by only $2,700.

Mexico’s National Energy Efficiency Standards

Mexico is a leader among developing countries in building and appliance energy efficiency standards and could serve as a model for other nations that want to implement or strengthen standards.

Mexico’s first mandatory standards came into force in 1994 for residential refrigerators, air conditioners, and three-phase electric motors, all important electricity-consuming devices in Mexico. Coverage has since expanded to 29 types of appliances, equipment, and building components. The law establishing Mexico’s standards requires them to be updated every five years, helping to avoid stagnation.

Mexico intentionally selected the stringency of its standards and designed its test procedures to mirror those used in the U.S. This harmonization lowered barriers to the trade in these appliances and expanded the market for Mexican manufacturers. Mexican exports of refrigerators to the U.S. “increased nine-fold from 401 million U.S. dollars to about 3.7 billion U.S. dollars” per year from 2000 to 2014, whereas the domestic Mexican market only doubled during that period.

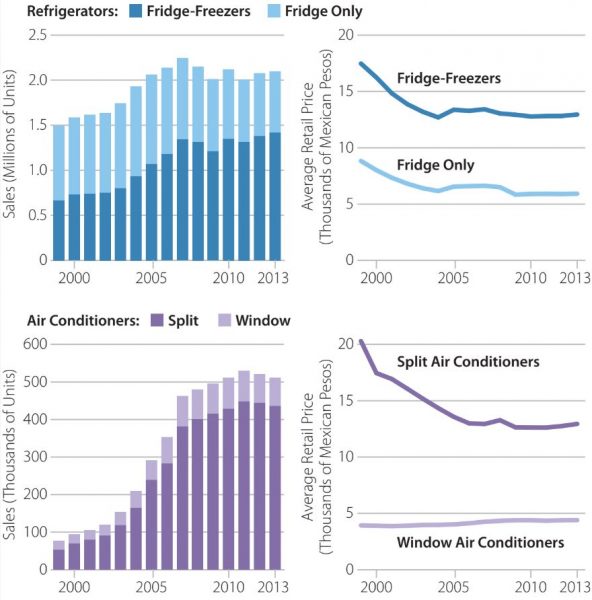

The implementation of energy efficiency standards did not lead to higher prices for consumers. The domestic Mexican market for combination refrigerator/freezers, refrigerators, split air conditioners, and window air conditioners grew considerably over the 1999 to 2013 period while per-unit prices of all these technologies dropped (except for window air conditioners, which remained flat).

Mexican refrigerators and air conditioners have become cheaper while becoming more efficient. Source: Lawrence Berkeley National Laboratory.

During this period, the devices’ features increased while durability and quality were not harmed. The most likely explanation for the price declines is that Mexican manufacturers and importers were able to take advantage of economies of scale and adapt successfully to more stringent efficiency requirements while keeping prices down.

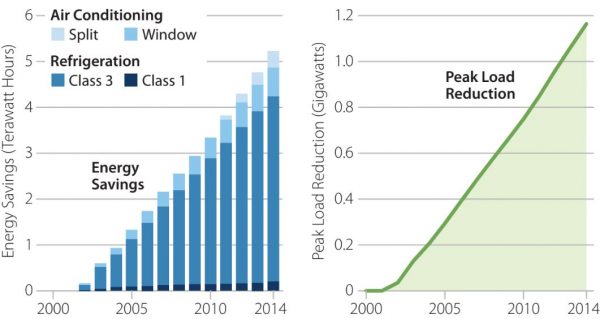

The standards also led to reductions in overall electricity use and in peak-time demand, reducing costs to society and lowering greenhouse gas and conventional pollutant emissions.

Energy efficiency standards for Mexican refrigerators and air conditioners have reduced total and peak energy use. Source: Lawrence Berkeley National Laboratory.

Mexico eased implementation of its standards by involving many stakeholders. Representatives from the private sector, equipment manufacturers, academia, the government, and non-government organizations all participate in an advisory committee that guides the standard-setting process. Industry representatives have praised the standards for allowing them to compete on a fair playing field and for signaling that investments in improved manufacturing processes and technology would be rewarded.

The standards have not been without downsides for Mexican manufacturers. The same improvements in energy efficiency that opened up the U.S. market to Mexican products have caused those products to be less competitive in developing Central American nations that lack energy efficiency standards. Consumers in these nations can buy inefficient, Asian-made devices more cheaply than Mexican equipment, and as a result, Mexican exports of equipment to Central American nations have dropped.

This holds a lesson for developing countries that manufacture appliances for export: It may be wise to harmonize standards with a large export market to offset any drop-off in sales to developing markets that lack efficiency standards. Alternatively, groups of economically interrelated developing countries may consider enacting standards all at once, as a regional coalition, to prevent the loss of market share to inefficient imports from outside the coalition.

Conclusion

Building codes and appliance standards are a key policy for reducing emissions from the building sector, which is particularly important in rapidly urbanizing countries. Standards are effective at overcoming various market barriers that are common in the building sector and limit the effectiveness of economic incentive policies.

When properly implemented, standards drive down emissions year after year while achieving net savings for society. The best standards in the world are technology finding, are publicly known years in advance, are resistant to gaming, and have built-in mechanisms to tighten the standards over time.

Proper monitoring and enforcement of building codes and appliance standards can be a particular challenge. However, when well written and enforced, building codes are a crucial way to save energy, reduce emissions, and save money—steps on the path to a clean energy future.