Vehicle Performance Standards

Potential emissions reductions from vehicle performance standards.

In 2014, the transportation sector emitted 7.5 billion tons of CO2e, representing 15% of global greenhouse gas emissions. Transportation emissions are forecast to grow 30% by 2030, spurred primarily by a large increase in vehicles sold in China and India. Vehicle performance standards have historically been very successful in driving down vehicle emissions, and robust vehicle performance standards can contribute about 3% of the cumulative global emission reductions needed to meet the two-degree Celsius target.

Vehicle performance standards specify minimum performance requirements that every vehicle must meet, thereby affecting the lowest (worst-performing) segment of the marketplace. They force manufacturers to either improve their vehicles or stop selling the most polluting vehicle models and instead sell their better-performing vehicles.

Vehicle performance standards work irrespective of whether consumers care about fuel efficiency by mandating minimum efficiency levels, making vehicle performance standards a good fit for countries or regions with buyers who have limited information or are insensitive to fuel efficiency.

However, design is important. All vehicle performance standards should have, at minimum, four policy components built in:

- Create long-term certainty to provide businesses with a planning horizon by including a known schedule of performance requirements over a long time frame.

- Build-in continuous improvement, so the standards strengthen over time to avoid stagnating and failing to deliver.

- Focus on outcomes, not technologies to avoid restricting innovation, by prioritizing physical outcomes that provide companies the greatest latitude for innovation so they can seek out the least expensive or most efficient means of achieving the standard.

- Prevent gaming via simplicity and avoiding loopholes – one of the more challenging aspects to designing effective vehicle performance standards, but a critically important priority.

Policy Description And Goal

Vehicle performance standards, often called fuel economy standards, establish maximum allowable levels of fuel consumption or greenhouse gas emissions per unit distance traveled. Their objective is to ensure that all vehicles, either individually or as a weighted average of sales, achieve certain minimum performance targets, thereby raising the vehicle fleet’s energy efficiency and reducing emissions. Past vehicle performance standards have reaped outstanding benefits: lower oil consumption, lower greenhouse gas emissions, reduced dependence on oil imports, and increased investment in innovative technologies, all at a net savings to society.

Vehicle performance standards are particularly valuable because market barriers may limit the efficacy of other transportation sector policies, such as vehicle and fuel fees and feebates, in delivering deep energy and emission reductions.

Vehicle performance standards have been implemented in a variety of ways in different countries. When designing the policy, some of the major choices to be made are:

- How to differentiate the standard for different vehicle types (trucks, cars, etc.)

- Whether to cover all types of vehicles under the standard or whether to exclude certain vehicle types, such as two-wheeled or three-wheeled vehicles. Generally, all vehicles should be covered

- Whether the standard should control the amount of fuel consumed or the amount of greenhouse gases emitted per unit distance traveled. For many jurisdictions, standards should ideally be emission based, which better accounts for leaking refrigerant from air conditioning systems and allows the use of other control technologies, which are relevant for non-CO2 However, some jurisdictions may prioritize oil conservation and create a standard intended primarily to reduce fuel consumption

- Whether the standard will make distinctions based on vehicle weight, vehicle footprint, or other design factors. If any distinction is required, it should be based on footprint (its two-dimensional projected area on the ground)

- Whether the standard has built-in, automatic improvement, or whether it must be manually reviewed by a legislative or regulatory body for each update. Ideally, standards should have a built-in improvement mechanism

- Whether the performance standard in a given year is defined as a continuous function for each vehicle type (with respect to an independent variable reflecting the vehicle’s design, such as footprint) or whether performance targets take the form of discrete stairsteps

- Whether to apply a standard to every vehicle sold or to apply the standard as a sales-weighted average of vehicles of a given type sold by a particular manufacturer. A sales-weighted average allows more flexible compliance options. A hybrid option is possible as well. For example, China sets both fleet-wide average standards and a minimum requirement for each model in a specific class

When To Apply This Policy

Using vehicle performance standards is almost always smart policy: They save society money while driving down emissions. However, there are particular policy objectives for which these standards are well suited and others that are not well suited, leaving a role for complementary transportation sector policies such as fuel fees and vehicle feebates, which are discussed in the next section.

When to Apply Vehicle Performance Standards

When standards specify minimum performance requirements that every vehicle must meet, they affect the lowest (worst-performing) segment of the marketplace. They force manufacturers to either improve their vehicles or stop selling the most polluting vehicle models and instead sell their better-performing vehicles. This approach has advantages.

For example, efficient vehicles already exist in the marketplace for virtually every vehicle class. Most manufacturers already produce models with a range of performance characteristics, which demonstrates the feasibility of complying with the standards. Therefore, standards are a particularly good fit for regions where some vehicle manufacturers sell significant numbers of inefficient vehicles, whether due to older technology or by favoring larger vehicles, such as SUVs.

When standards are specified as minimum performance requirements on a sales-weighted average basis (for each vehicle type, for each manufacturer), manufacturers may improve the worst-performing vehicles they sell, or they may improve the best-performing vehicles and sell more of them (offsetting the emissions from the worst-performing vehicles), or both.

This helps guide not only manufacturers’ design choices when developing or refining new vehicle models but also their marketing and pricing choices, to ensure the sales-weighted average hits the target. If vehicle manufacturers that over-comply on a sales-weighted average basis are allowed to sell this credit to other manufacturers who may then legally under-comply with the standard, the policy gives efficiency leaders an incentive to innovate further so as to have more credits to sell to other manufacturers. This design is good for countries or regions that can establish, monitor, and prevent cheating on a credit trading marketplace.

Another factor to consider when deciding to apply vehicle performance standards relates to overcoming market irrationalities and barriers. Although evidence is mixed, many studies have found that consumers significantly undervalue fuel savings when making their purchasing decisions.

Unlike economic incentives (taxes or subsidies), a performance standard does not rely on consumers making rational adjustments to their behavior in response to an economic signal. A performance standard will work irrespective of whether consumers care about fuel efficiency or even in the case where consumers buy vehicles without knowledge of their fuel efficiency. This makes standards good fits for countries or regions with buyers who have limited information or are insensitive to fuel efficiency.

Vehicle performance standards are additionally important in the face of fuel price uncertainty. Consumers might be likely to undervalue fuel savings, but they also often don’t have good information about fuel prices, which can fluctuate drastically even within the timeframe it takes to make a vehicle purchase decision. Manufacturers and consumers alike benefit from standards that prepare and protect them from volatile oil prices.

When to Apply Complementary Policies

Several worthy policy goals are not tackled by vehicle performance standards:

First, standards affect only new vehicles; they do not encourage the retirement or replacement of old, inefficient vehicles. In practice, this means vehicle performance standards have a long lead time after the policy is enacted before their full emission benefits are realized. A policy to encourage the early retirement of old vehicles—such as government buyback and scrapping of inefficient vehicles (“cash for clunkers”)—may be a helpful complement that accelerates the impact of vehicle performance standards.

Second, among vehicles that comply with the standard, the policy provides no incentive for a buyer to select one of the best-performing options rather than one that narrowly complies. A performance standard is weaker than some other policies at pushing consumers to adopt cutting-edge technology and at encouraging manufacturers to produce innovative, extremely efficient new models. That said, fleet average standards that allow manufacturers to sell a mix of high-performing and low-performing vehicles are likely to result in more of an innovation push than standards that simply set a minimum requirement per vehicle, especially if less efficient vehicles are cheaper or more likely to sell. Additionally, in some systems over-complying manufacturers may sell credits to other manufacturers, meaning some manufacturers can just buy their way out of compliance. A pricing policy that provides financial rewards that increase with vehicle efficiency, such as a feebate, helps mitigate this weakness.

Third, a vehicle performance standard does not reduce the amount a vehicle is used. In fact, by lowering the cost of travel, a vehicle performance standard can actually encourage an increase in vehicle use. Studies vary in estimating this effect, but it is reasonable to conclude that a 10% increase in vehicle efficiency results in roughly a 2% to 4% increase in vehicle use. Although the rebound effect is not trivial, it is more than offset by savings from the fuel economy standards.

For example, assuming an average distance traveled of 12,000 miles per year, increasing a vehicle’s efficiency from 25 miles per gallon to 30 miles per gallon would result in a reduction of 80 gallons per year without the rebound effect and 73 gallons per year assuming a rebound effect of 10%. Although the rebound effect reduces the amount of fuel saved by about 7 gallons per year, the net savings of 73 gallons vastly outweighs this effect.

Fourth, policies governing planes and ships, often used for international transport, tend be set internationally. The International Civil Aviation Administration has recently set the first-ever vehicle performance standards for aircraft, and the International Maritime Organization is doing something similar for oceangoing vessels.

In these cases, rather than setting their own vehicle performance standards (and generating a patchwork of regulations), policymakers can adopt and enforce the standards set by these organizations. As members of these groups, countries may push these bodies to enact strong, well-designed standards. Aviation and marine emissions are already a significant source of emissions, and addressing emissions from these sources will become increasingly important as the rest of the transportation system becomes electrified and decarbonized.

Detailed Design Recommendations

The following policy design principles apply to fuel economy standards.

Create Long-Term Certainty to Provide Businesses with a Fair Planning Horizon

Vehicle and auto manufacturers may need several years to make the necessary investment in research and development (R&D) necessary to meet fuel economy standards. If standards are set only a few years at a time, businesses may be unsure whether standards will continue to become more stringent in the future. In turn, they will not know whether modest investment in near-term improvements is sufficient or whether a larger investment in a new technology or major design change might be worthwhile.

Because of their greater size and complexity, the design cycle for aircraft and oceangoing ships is even longer than for automobiles, so a long-term planning horizon is even more crucial for these industries.

A known schedule of vehicle performance standards helps companies justify investments in R&D and fuel efficiency to their shareholders, who otherwise might be skeptical of the value of these expenditures. Companies that make a serious commitment to R&D may see tighter standards as their competitive advantage.

Build in Continuous Improvement

Vehicle performance standards are valuable because they continue to drive the vehicle fleet toward greater efficiency and eliminate the worst-performing vehicles over time. If the standards are allowed to stagnate (i.e., remain the same for a significant period of time), they are not serving their primary purpose.

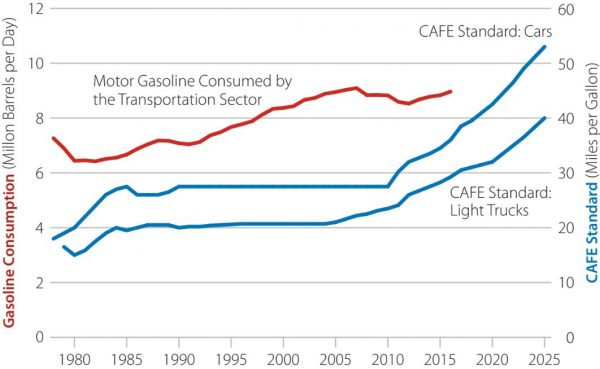

After the 1973 oil crisis, the U.S. government enacted the first set of automobile fuel economy standards, which came into effect in 1978. From 1978 to 1985, the standards for passenger cars rose from 18 miles per gallon to 27.5 miles per gallon. In that time, U.S. motor gasoline consumption dropped from 7.3 million barrels per day to 6.7 million barrels per day, despite a growing U.S. economy and population.

Other factors probably influenced this drop as well, such as a change in the federal highway speed limit and higher gasoline prices. However, total passenger travel increased over this period, indicating that at least part of the reduction in motor gasoline demand was due to more efficient vehicles.

Unfortunately, the standards were then allowed to stagnate for two decades. Despite various attempts, it was not until December 2007 that legislation tightening the standards was passed. Motor gasoline consumption rose considerably in the intervening decades, reaching 9.1 million barrels per day in 2007. This stagnation of standards resulted in a tremendous loss to the U.S. economy: one to three million barrels of oil per day, worth tens of billions of dollars per year, and hundreds of millions of tons of greenhouse gas emissions and other air pollutants that cause illness and premature death.

To avoid these negative outcomes, policies should have a built-in mechanism for tightening standards.

One way in which a standard might build in continuous improvement is to specify a formula for increasing stringency (3%–6% per year is a reasonable guideline). This provides the greatest clarity and certainty to manufacturers, but it risks being unachievable if technical or physical bottlenecks are reached, which becomes increasingly likely after the standard has been tightened for many years, all low-hanging fruit is gone, and only the hardest technical challenges remain.

On one hand, it may not be worth worrying about this when designing a standard, because the combined power of technological innovation and free markets continuously cough up huge advances, so today’s efficiency frontier often becomes tomorrow’s benchmark. Alternatively, it is possible to include a “safety valve,” for example, allowing the standards to stop tightening if an independent technical review board determines that further improvements do not meet a cost-effectiveness test.

U.S. gasoline consumption increased while fuel economy standards stagnated. Source: U.S. Energy Information Administration.

Another approach is to set the standard based on the most efficient vehicles already in the marketplace, plus a technology improvement factor, as is done in the Top Runner program in Japan.

Focus Standards on Outcomes, not Technologies

Vehicle performance standards should not specify the technology to be used but rather the physical outcomes they aim to achieve. For example, a good standard will regulate the amount of CO2 emitted for each vehicle-kilometer (or when it is more applicable, each freight-ton-kilometer) traveled or transported. It should not specify, for example, that a particular engine design be used. This leaves companies the greatest latitude for innovation, so they can seek out the least expensive or most efficient means of achieving the standard.

Prevent Gaming via Simplicity and Avoiding Loopholes

Potentially the greatest difficulty in designing good vehicle performance standards is avoiding gaming and loopholes. For example, standards that vary based on vehicle weight (which allow greater fuel consumption for heavier vehicles) may encourage manufacturers to make heavier, less efficient vehicles. In the United States, standards that were more lax for light trucks than for cars encouraged manufacturers to categorize more of their vehicles as sport utility vehicles (SUVs, technically a type of light truck) and to promote these larger vehicles to consumers.

Some principles that help to avoid loopholes include:

- Keep the standards simple. Write in clear and unambiguous language the quantitative performance outcome to be achieved. Carving out exceptions or special cases for various technologies or for vehicles with various properties opens up opportunities for gaming

- Create real-world, in-use testing protocols, with real damages for cheats or nonperformance. Weak or inaccurate tests allow manufacturers to produce vehicles with nice fuel economy stickers but lousy real-world performance. Language that says “tests will be modified from time to time to better represent real-world conditions” and sets a fair horizon for future test requirements (e.g., five years) can push manufacturers to design for the world rather than the test

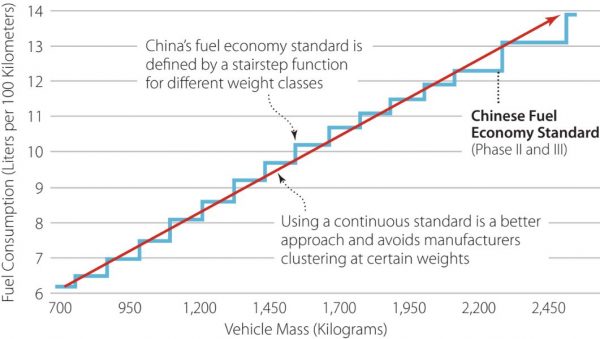

- If the standard must vary by vehicle characteristics, it should do so smoothly rather than ratcheting up or down suddenly when the vehicle characteristic crosses a certain threshold. For example, a vehicle performance standard might specify that the minimum required performance is equal to the vehicle’s footprint multiplied by a coefficient rather than by breaking vehicles into distinct categories based on their footprints falling within particular ranges. A standard that changes abruptly makes a stairstep pattern when graphed against the characteristic on which the standard is based (such as vehicle footprint). Manufacturers will design vehicles that all fall at one edge of a stairstep, constraining their design choices and possibly increasing vehicle price without any emission benefit relative to setting a standard as a smooth line or curve that passes through the endpoint of each stairstep

A continuous standard would avoid issues with China’s stair-step fuel economy standard. Source: International Council on Clean Transportation.

- Similar standards should apply to vehicle types that are substitutes for one another, such as passenger cars and SUVs (which are overwhelmingly used as on-road vehicles in the same functional capacity as passenger cars). This reduces the incentive for manufacturers to market and sell primarily the vehicle type with the weaker standards

Additional Design Considerations

If vehicle performance standards are designed according to the aforementioned principles, there are only a few remaining points to watch out for.

Use Emissions-Based Standards for Environmental Goals

If the policy goal is to reduce emissions, it is best if vehicle performance standards are based not on fuel consumption but on pollutant emissions per distance (or per unit cargo-distance) traveled. The effect is largely similar, but there are two key differences:

- For local air pollutants, an emission-based standard allows control technologies, such as particulate filters, to be used to help meet the standard. This helps ensure the standards are technology finding (rather than restricting manufacturers’ options to choose among technologies addressing fuel efficiency), allowing compliance at least cost

- For greenhouse gases, an emission-based standard should include leakage of refrigerant from the vehicle’s air conditioning system. These refrigerants can be powerful greenhouse gases, and the fuel efficiency of the car has no relationship to their leakage rate

On the other hand, if the policy goal is to reduce petroleum consumption, then vehicle fuel consumption performance standards are more appropriate.

Build Industry Support

Vehicle manufacturers may either oppose the enactment of tighter vehicle performance standards (as they did in the U.S. in 1990) or work constructively with policymakers on a compromise (as they did in the U.S. in 2009). The support of automakers can make a big difference in the likelihood that a legislature or a regulatory agency feels comfortable enacting suitable performance standards, and it may avoid the uncertainty and delay associated with lawsuits challenging the regulations.

The core elements of smart policy design will help garner the support of automakers who have serious commitments to new technology. In particular, automakers value reasonably long lead times, regulatory certainty, flexibility in how a standard is met (technology-finding policy), and the opportunity to trade, bank, or borrow credits. Of course, companies that fail to make meaningful technology development investments may still oppose tighter standards, but it makes little sense to design policy to protect the worst performers.

Industry players, especially vehicle manufacturers (as opposed to vehicle component manufacturers), are more likely to be supportive if they are given a place at the table early, a voice in setting the starting stringency of the new standards, and regulatory certainty through a known schedule of improvements extending many years into the future.

Attempts by industry to set up periodic review of the standards should be viewed with skepticism, as reviews add to uncertainty and are often used to undermine the stringency of existing standards. If a review is called for, it should be conducted by qualified, independent experts.

Some vehicle and engine manufacturers may be supportive if they believe R&D is among their competitive strengths. Cummins is a U.S. company that manufactures engines and power generation equipment. John Wall, Cummins’s chief technology officer, explained why Cummins has supported increased vehicle performance standards in the past: If Cummins knows the standards it will need to meet, it can invest in developing the necessary technologies, such as hybrid power trains or heat recovery systems. When the standard comes into effect, Cummins can provide standard-compliant products that are better and cheaper than those of their competitors, and Cummins gains market share and a return on its R&D investment.

Use Test Procedures Resembling Real-World Driving Conditions and Re-Test Randomly Selected Vehicles

Vehicle performance standards can be undermined by test procedures that are intentionally or unintentionally designed to allow manufacturers to achieve good test results while achieving worse real-world, on-road performance. This has been a particular problem in Europe, where the gap between vehicles’ tested performance and their actual performance continues to grow, as manufacturers game the test procedure: This gap was 10% in 2001 and grew to 35% by 2014.

This means the average car in Europe that appears to comply with the standard actually burns 35% more fuel than demonstrated during the test procedure. Vehicle manufacturers are able to supply specially prepared vehicles for testing; for example, they can take out the seats to make the car lighter, tape the seams to make it more aerodynamic, and fill the tires with liquid to reduce their rolling resistance. They can even select an especially favorable test track to be used. This “golden car” approach is gaming the system across the board, but because of poor policy design, it is legal.

Vehicles should be tested upon introduction to market and retested during the vehicles’ lifetime. Testing should be carried out by an independent third party and on randomly selected vehicles, not vehicles specially prepared for testing by manufacturers. Laboratory tests should be supplemented by on-road tests that reflect actual driving conditions.

Some car and part manufacturers and international bodies are pushing for internationally harmonized standards for vehicle testing procedures, which would arguably strengthen enforcement and better identify under-performers. However, some nations and regions (such as the U.S. and the European Union) prefer to have their own testing procedures to better account for local conditions. The success of internationally harmonized testing standards will depend on the ability of stakeholders to implement standards that promote rigorous, randomized testing in accordance with the principles outlined above.

Case Studies

Japan’s Top Runner Program for Passenger Vehicles

Japan has had vehicle performance standards for passenger vehicles since 1979, but in 1999 they were brought under the scope of Japan’s new Top Runner program. The program first identifies the most fuel-efficient vehicle in each weight class every few years. The efficiency standard is then updated to reflect the efficiency of this “top runner” vehicle but adjusted to account for potential technological improvement over the next set of years the standard covers.

This technological improvement percentage, which is determined by regulators and subject to a public comment period, pushes manufacturers to achieve vehicle efficiency above and beyond what is currently in the market, incorporating the principle of continuous improvement discussed earlier. To push the boundaries of technology, tax breaks are offered to companies that meet the performance standards years ahead of schedule.

The Top Runner program sets standards based on the sales-weighted average efficiency of vehicles sold by each manufacturer, so manufacturers can sell some vehicles that do not meet the standard as long as they sell enough vehicles that exceed the standard by a sufficient margin. The Top Runner program also stipulates “display items,” or statistics about each product that must be displayed in places that can be readily seen by buyers, such as in catalogs and on exhibits. The data to be included vary by product. For passenger vehicles, required data include the engine type, vehicle weight, riding capacity, energy consumption efficiency, emissions, and other details.

Between 1999 and 2010, the Top Runner program improved the energy efficiency of passenger vehicles by 23% and improved the efficiency of small freight vehicles by 13%.

Although the Top Runner program has seen some success, it has significant drawbacks. One limitation is that the program categorizes vehicles by weight class rather than by footprint, encouraging manufacturers to build bigger vehicles. Another limitation is that although the standard includes a mechanism for increasing stringency, this mechanism relies on technology that is already in production in the baseline year, resulting in standards that are easily met.

For example, although the program has resulted in a 49% improvement in efficiency, this improvement has taken place over 15 years, delivering only a 2.7% improvement per year. Third, Top Runner uses a stairstep function in setting efficiency requirements and therefore encourages gaming. It’s worth noting that this type of program is also much easier to implement once top-performing technologies are already available; it would not be as effective for an initial program in countries that are new to performance standards.

China’s Vehicle Fuel Consumption Control Program

China has introduced vehicle fuel economy standards in four phases, with the first phase covering 2004–2007, the second phase 2008–2011, the third phase 2012–2015, and the fourth phase taking effect at the start of 2016.

Although the program currently fails to incorporate many of the design principles discussed earlier, policymakers are taking lessons from global leaders in vehicle performance standards to improve on several of its current deficiencies. China’s standards have seen some success and hold some promise for future efficiency improvement.

China’s vehicle fuel consumption standard varies based on vehicle weight, not footprint, and establishes different standards for different technologies (normal, SUV, and minivan). Each phase extends only about four years, failing to give businesses certainty and a long-term planning horizon.

New standards are rolled out only three years before manufacturers need to demonstrate compliance, which results in slower and more expensive technology upgrades, as manufacturers are limited in their ability to plan for the long term. The standard is implemented as a series of stairsteps rather than a continuous function (although in the future it will probably move to a continuous function) and relies heavily on manufacturer input. Lastly, policies focus on fuel consumption rather than pollutant emissions.

For compliance and enforcement, China uses a European test protocol for monitoring, verification, and enforcement, but Europe’s test protocols (as discussed earlier) allow extensive gaming by manufacturers. Compliance is also demonstrated using preproduction and production models tested in labs rather than testing models on the road. Furthermore, there are no compliance penalties and no compliance follow-ups once vehicles are on the road. China is creating its own testing protocol, but whether that will turn out to be tougher or looser than the European approach remains to be seen.

Taken together, the Phase I and Phase II standards reduced real-world average fuel consumption of vehicles by approximately 12%, a reduction that would have been greater but for the fact that the standards encouraged the production of higher-fuel-consuming cars with larger engine displacement, eliminating some of the reduction in total fuel consumption.

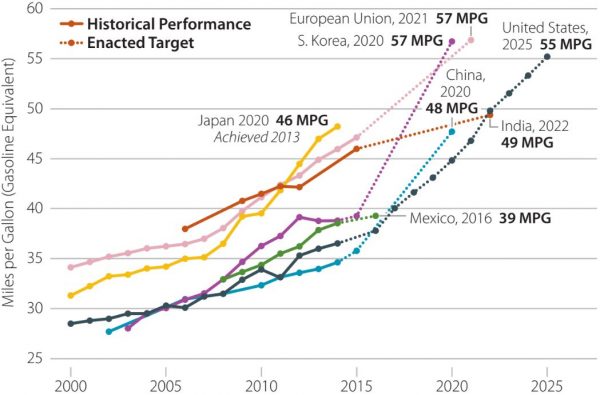

The strongest fuel economy standards in the world. Source: International Council on Clean Transportation.

On the upside, the efficiency requirement of China’s standard is aggressive, making the Chinese fuel economy standard one of the most stringent in the world. China supplements its fuel economy standards with a variety of other policies, including fuel taxes; subsidies for fuel-efficient, plug-in hybrid, and all-electric vehicles handled upstream of the consumer; a commitment to scrapping old and high-emitting vehicles (although the policy mechanism has not yet been announced); and a tax and rebate that together encourage the purchase of smaller engines. China also requires labels disclosing the fuel efficiency of vehicles, although as of 2012, one study found only a 62% compliance rate with requirements for cars to display these labels.

The Chinese fuel economy standards are for the most part well designed and effective, although they would benefit from better testing and enforcement procedures and from being based on footprint rather than weight.

The United States’ Corporate Average Fuel Economy Standards

The U.S. fuel economy policy is the Corporate Average Fuel Economy (CAFE) standard. First coming into force in 1978, the CAFE standard aims to improve the average fuel economy of newly sold light-duty vehicles. CAFE is applied to a manufacturer’s current model-year fleet of passenger cars or light trucks, manufactured in the U.S. and with a gross vehicle weight rating of 8,500 pounds (3,856 kilograms) or less. Manufacturers are required to meet an average fuel economy target based on the sales-weighted mean miles per gallon in a given year.

The penalty for noncompliance is steep: If a manufacturer’s new vehicle fleet falls below the applicable standard, the manufacturer must pay a penalty, currently U.S. $55 per mile per gallon below the standard, per vehicle manufactured for the U.S. market.

In 2012, after passage of the 2007 Energy Independence and Security Act, the National Highway Traffic Safety Administration established a credit trading mechanism to allow manufacturers to transfer compliance credits between car and truck categories, carry compliance credits forward up to five model years, and transfer compliance credits between firms.

During this revision, the method of calculating compliance was changed to the product of the vehicle’s wheelbase and its average track width (footprint). On one hand, the change loosened the standards by allowing larger vehicles to meet less aggressive fuel economy requirements than smaller vehicles, reducing the incentive to sell more small cars. On the other hand, by indexing the standard to vehicle size rather than weight, this formula builds in a crucial incentive to reduce weight, which enables improved fuel economy and can improve overall roadway safety.

The U.S. CAFE standard is often seen as a success and in recent years has significantly driven fuel economy improvements. However, without a mechanism to regularly improve the stringency of the standard, fuel economy stagnated for nearly 20 years between 1990 and 2010. Given the current administration in the U.S., it is unclear whether the standards will continue to strengthen in the future or whether they will stagnate again.

In addition, the standards are set separately for passenger cars and light-duty trucks, which has encouraged manufacturers to make small modifications that reclassify passenger cars as light-duty trucks, thereby lowering the minimum required fuel economy.

Another issue is the inclusion of a review process for future year standards. During the 2012 extension of the standards, policymakers included the option of a midterm review of the standards, which manufacturers are trying to use as a mechanism for reducing the standards stringency.

Nevertheless, the long time horizon, flexible compliance options, and use of standards based on footprint (rather than weight) have helped the U.S. CAFE standards improve vehicle fuel economy in recent years.

Conclusion

Vehicle performance standards are one of the best policies for reducing emissions in the transportation sector. When properly implemented, they drive down emissions year after year while achieving net savings for society.

The best standards in the world are publicly known many years in advance, have built-in mechanisms to tighten the standards over time, are technology finding, and are resistant to gaming. Well-designed standards and proper enforcement will be a key part of the transition to a clean energy future.